Deja un mensaje

¡Te llamaremos pronto!

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!

PRESENTACIóN

Más información facilita una mejor comunicación.

SEÑOR

- SEÑOR

- - ¿ Por qué no?

Okay

¡Enviado satisfactoriamente!

¡Te llamaremos pronto!

Okay

Deja un mensaje

¡Te llamaremos pronto!

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!

PRESENTACIóN

Calificación general

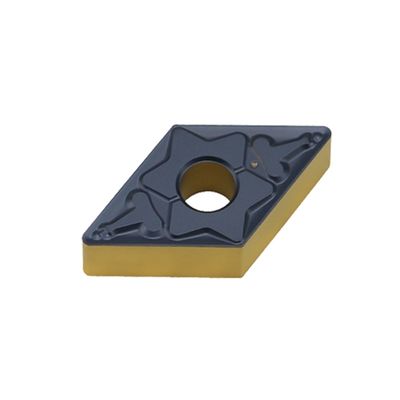

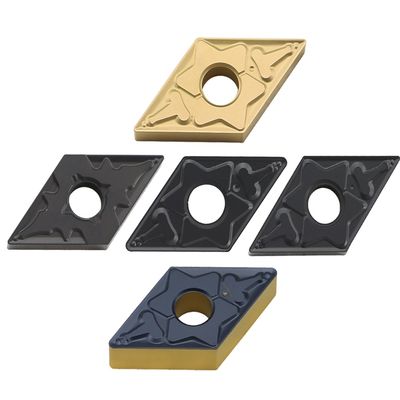

Imagen de calificación

La siguiente es la distribución de todas las calificacionesTodas las reseñas